What Are the Benefits of Implementing a Dust Control Sprinkler System?

By Kieran Naik on Jan 16, 2026 11:00:01 AM

Quartz-based crystalline silica, found in most rock, sand, and gravel processed at quarries, poses a serious health hazard when disturbed. The chronic inhalation of respirable silica dust can lead to potentially fatal lung diseases: in the UK alone, approximately 600,000 workers are exposed to silica dust each year and 12,000 die from silicosis.

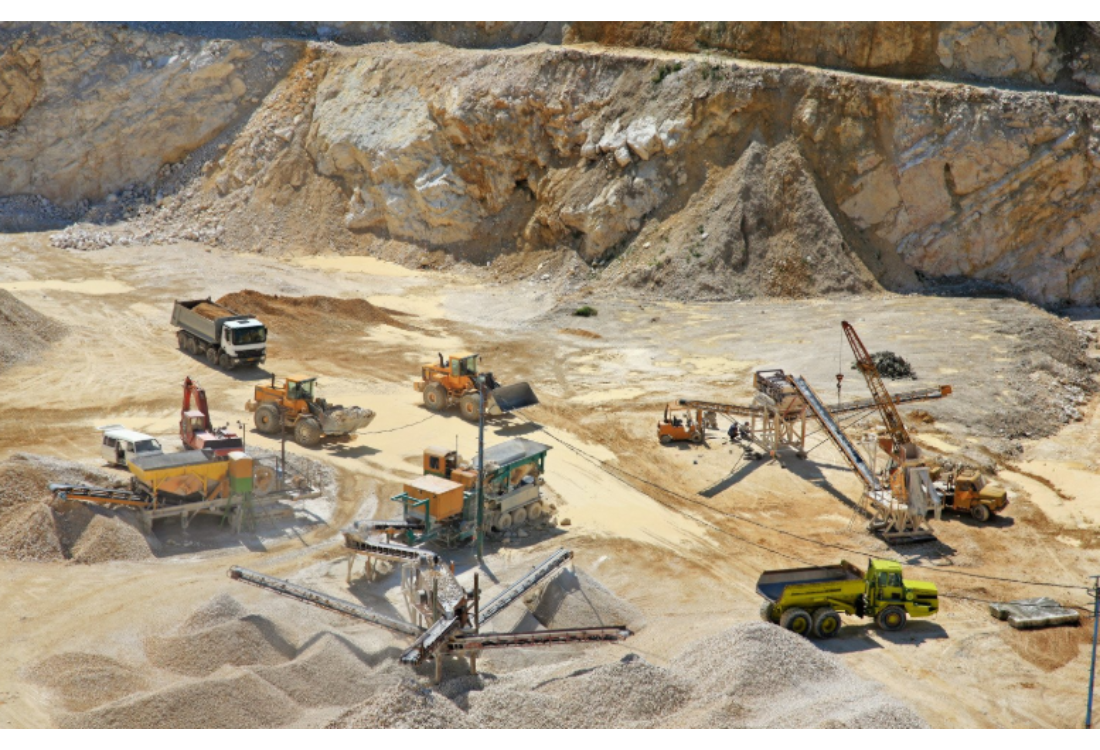

For quarry managers, controlling airborne dust is essential to protect workers, safeguard equipment, and reduce operational downtime. Purpose-built sprinkler systems for dust control offer an efficient and low-maintenance method to suppress fine particles at source. This article explores the key benefits of installing a dust control sprinkler system.

Dust control sprinkler system: advantages and benefits

In high-risk areas, such as haul roads, stockpiles, crushing zones, and loading points, airborne dust particles can rapidly reach hazardous concentrations, especially those containing respirable crystalline silica. A well-designed dust suppression sprinkler system delivers consistent, reliable coverage to bind these harmful particles and reduce the risks of inhalation.

Respirable silica dust is directly linked to silicosis, a progressive and irreversible lung disease. It also contributes to chronic obstructive pulmonary disease (COPD) and other serious respiratory conditions. For quarry managers, reducing dust exposure should be a priority to comply with health and safety laws, and prevent long-term or fatal illness among the workforce.

Compared to manual spraying or ad hoc dust suppression efforts, automated sprinkler systems are far more efficient and consistent. Many can be zoned or timer-controlled, enabling targeted operation during peak dust generation activities such as drilling, blasting, or material transfer.

The key benefits of a dust control sprinkler system include:

-

Reduced exposure to respirable crystalline silica and fine particulate matter

-

Prevention of serious respiratory diseases such as silicosis and COPD

-

Consistent dust control in critical zones

-

Improved visibility and site safety for workers and machinery operators

-

Reduced reliance on manual spraying, reducing labour and equipment costs

-

Support for compliance with Health and Safety Executive (HSE) dust exposure limits

-

Cleaner, more environmentally responsible site operations

Water conservation methods in dust control

While water is a vital tool for dust suppression, uncontrolled application can lead to excessive consumption, runoff, and erosion. A water sprinkler system for dust suppression is engineered to deliver effective dust binding while conserving water.

Modern systems utilise the latest technology, including:

-

Pressure-regulated pumps to control flow

-

Optimised nozzles that produce fine mist with minimal drift

-

Programmable control panels for timing and zoning

-

Optional integration with sensors or dust monitors

to activate only when needed

This precision ensures that water is used efficiently to suppress dust without creating surface hazards such as mud or slippery ground.

Broader industry applications

Although dust suppression sprinklers are often associated with quarries and mining operations, they are equally valuable in other sectors, such as demolition, recycling, cement manufacturer, grain processing, and bulk material storage and loading. Sprinkler-based systems deliver measurable improvements in air quality, operational safety, and environmental impact, making them a scalable and sustainable dust control solution for many industries.

Get in touch to find out more

At Best-Chem, we design and deliver dust control sprinkler systems that are tailored to the specific needs of quarry operations and other high-dust industries. To find out more about how can help you to improve site safety, efficiency, and environmental performance, please contact us today.

You May Also Like

These Related Stories

What Is Silica Dust And How Does It Impact Operations And Safety On Site?

Managing The Health Risk Of Respirable Crystalline Silica In Quarries

No Comments Yet

Let us know what you think